JOIN IT HERE: http://www.facebook.com/pages/Say-YES-to-Nuclear-Energy/130703406966436?sk=wall

Greenuke4Malaysia

Tuesday 9 August 2011

Support Nuclear on Facebook!

SHOW YOUR SUPPORT OF NUCLEAR ENERGY ON FACEBOOK NOW.

JOIN IT HERE: http://www.facebook.com/pages/Say-YES-to-Nuclear-Energy/130703406966436?sk=wall

JOIN IT HERE: http://www.facebook.com/pages/Say-YES-to-Nuclear-Energy/130703406966436?sk=wall

The concept behind the nuclear power plant

The diagram below shows the concept used in a nuclear power plant,based on gasification:

and the containment building plan to handle the disposable materials are shown as below:

Handling nuclear power plant safety in the event of an earthquake

- Japanese, and most other, nuclear plants are designed to withstand earthquakes, and in the event of major earth movement, to shut down safely.

- In 1995, the closest nuclear power plants, some 110 km north of Kobe, were unaffected by the severe Kobe-Osaka earthquake, but in 2004, 2005, 2007, 2009 and 2011 Japanese reactors shut down automatically due to ground acceleration exceeding their trip settings.

- In 1999, three nuclear reactors shut down automatically during the devastating Taiwan earthquake, and were restarted two days later.

- In March 2011 eleven operating nuclear power plants shut down automatically during the major earthquake. Three of these subsequently caused an INES Level 7 Accident due to loss of power leading to loss of cooling and subsequent radioactive releases.

Design criteria

Because of the frequency and magnitude of earthquakes in Japan, particular attention is paid to seismic issues in the siting, design and construction of nuclear power plants. The seismic design of such plants is based on criteria far more stringent than those applying to non-nuclear facilities. Power reactors are also built on hard rock foundations (not sediments) to minimise seismic shaking.

Japanese nuclear power plants are designed to withstand specified earthquake intensities evident in ground motion. These used to be specified as S1 and S2, but now simply Ss, in Gal units. The plants are fitted with seismic detectors. If these register ground motions of a set level (formerly 90% of S1, but at Fukushima only 135 Gal), systems will be activated to automatically bring the plant to an immediate safe shutdown. The logarithmic Richter magnitude scale (or more precisely the Moment Magnitude Scale more generally used today) measures the overall energy released in an earthquake, and there is not always a good correlation between that and intensity (ground motion) in a particular place. Japan has a seismic intensity scale in shindo units 0 to 7, with weak/strong divisions at levels 5 & 6, hence ten levels. This describes the surface intensity at particular places, rather than the magnitude of the earthquake itself.

The former design basis earthquake ground motion or peak ground acceleration (PGA) level S1 was defined as the largest earthquake which can reasonably be expected to occur at the site of a nuclear power plant, based on the known seismicity of the area and local active faults. A power reactor could continue to operate safely during an S1 level earthquake, though in practice they are set to trip at lower levels. If it did shut down, a reactor would be expected to restart soon after an S1 event.

Larger earthquake ground motions in the region, considering the tectonic structures and other factors, must also be taken into account, although their probability is very low. The largest conceivable such ground motion was the upper limit design basis extreme earthquake ground motion (PGA) S2, generally assuming a magnitude 6.5 earhtquake directly under the reactor. The plant's safety systems would be effective during an S2 level earthquake to ensure safe shutdown without release of radioactivity, though extensive inspection would be required before restart. In particular, reactor pressure vessel, control rods and drive system and reactor containment should suffer no damage at all.

Safety aspect of a Nuclear Power Plant's Operation

- From the outset, there has been a strong awareness of the potential hazard of both nuclear criticality and release of radioactive materials.

- There have been three major reactor accidents in the history of civil nuclear power - Three Mile Island, Chernobyl and Fukushima. One was contained without harm to anyone, the next involved an intense fire without provision for containment, and the third severely tested the containment, allowing significant release of radioactivity.

- These are the only major accidents to have occurred in over 14,500 cumulative reactor-years of commercial operation in 32 countries.

- The risks from western nuclear power plants, in terms of the consequences of an accident or terrorist attack, are minimal compared with other commonly accepted risks. Nuclear power plants are very robust.

- Safety is achieved through "defence in depth".

Achieving optimum nuclear safety

- high-quality design & construction,

- equipment which prevents operational disturbances or human failures and errors developing into problems,

- comprehensive monitoring and regular testing to detect equipment or operator failures,

- redundant and diverse systems to control damage to the fuel and prevent significant radioactive releases,

- provision to confine the effects of severe fuel damage (or any other problem) to the plant itself.

The safety provisions include a series of physical barriers between the radioactive reactor core and the environment, the provision of multiple safety systems, each with backup and designed to accommodate human error. Safety systems account for about one quarter of the capital cost of such reactors. As well as the physical aspects of safety, there are institutional aspects which are no less important - see following section on International Collaboration.

The barriers in a typical plant are: the fuel is in the form of solid ceramic (UO2) pellets, and radioactive fission products remain largely bound inside these pellets as the fuel is burned. The pellets are packed inside sealed zirconium alloy tubes to form fuel rods. These are confined inside a large steel pressure vessel with walls up to 30 cm thick - the associated primary water cooling pipework is also substantial. All this, in turn, is enclosed inside a robust reinforced concrete containment structure with walls at least one metre thick. This amounts to three significant barriers around the fuel, which itself is stable up to very high temperatures.

These barriers are monitored continually. The fuel cladding is monitored by measuring the amount of radioactivity in the cooling water. The high pressure cooling system is monitored by the leak rate of water, and the containment structure by periodically measuring the leak rate of air at about five times atmospheric pressure.

Looked at functionally, the three basic safety functions in a nuclear reactor are: to control reactivity, to cool the fuel and to contain radioactive substances.

The main safety features of most reactors are inherent - negative temperature coefficient and negative void coefficient. The first means that beyond an optimal level, as the temperature increases the efficiency of the reaction decreases (this in fact is used to control power levels in some new designs). The second means that if any steam has formed in the cooling water there is a decrease in moderating effect so that fewer neutrons are able to cause fission and the reaction slows down automatically.

In the 1950s and '60s some experimental reactors in the Idaho desert were deliberately tested to destruction to verify that large reactivity excursions were self-limiting and would automatically shut down the fission reaction. These tests verified that this was the case.

Beyond the control rods which are inserted to absorb neutrons and regulate the fission process, the main engineered safety provisions are the back-up emergency core cooling system (ECCS) to remove excess heat (though it is more to prevent damage to the plant than for public safety) and the containment.

Traditional reactor safety systems are 'active' in the sense that they involve electrical or mechanical operation on command. Some engineered systems operate passively, eg pressure relief valves. Both require parallel redundant systems. Inherent or full passive safety design depends only on physical phenomena such as convection, gravity or resistance to high temperatures, not on functioning of engineered components. All reactors have some elements of inherent safety as mentioned above, but in some recent designs the passive or inherent features substitute for active systems in cooling etc. Such a design would have averted the Fukushima accident, where loss of electrical power resulted is loss of cooling function.

The basis of design assumes a threat where due to accident or malign intent (eg terrorism) there is core melting and a breach of containment. This double possibility has been well studied and provides the basis of exclusion zones and contingency plans. Apparently during the Cold War neither Russia nor the USA targeted the other's nuclear power plants because the likely damage would be modest.

Nuclear power plants are designed with sensors to shut them down automatically in an earthquake, and this is a vital consideration in many parts of the world. (see paper on Earthquakes)

The Three Mile Island accident in 1979 demonstrated the importance of the inherent safety features. Despite the fact that about half of the reactor core melted, radionuclides released from the melted fuel mostly plated out on the inside of the plant or dissolved in condensing steam. The containment building which housed the reactor further prevented any significant release of radioactivity. The accident was attributed to mechanical failure and operator confusion. The reactor's other protection systems also functioned as designed. The emergency core cooling system would have prevented any damage to the reactor but for the intervention of the operators.

Investigations following the accident led to a new focus on the human factors in nuclear safety. No major design changes were called for in western reactors, but controls and instrumentation were improved and operator training was overhauled.

By way of contrast, the Chernobyl reactor did not have a containment structure like those used in the West or in post-1980 Soviet designs.

At Fukushima Daiichi in March 2011 the three operating reactors shut down automatically, and were being cooled as designed by the normal residual heat removal system using power from the back-up generators, until the tsunami swamped them an hour later. The emergency core cooling systems then failed. Days later, a separate problem emerged as spent fuel ponds lost water. Full analysis of the accident is pending.

The effect nuclear fuel has on power generation prices

Here is a comparison of how much cheaper overall energy would be for the people of Malaysia if the nuclear power was used.

These show that a doubling of fuel prices would result in the electricity cost for nuclear rising about 9%, for coal rising 31% and for gas 66%. Gas prices have since risen significantly.

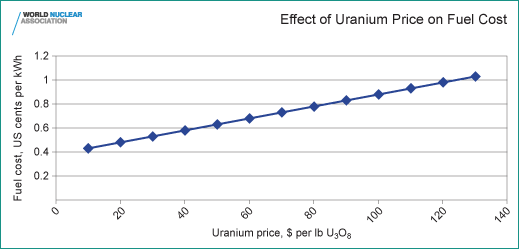

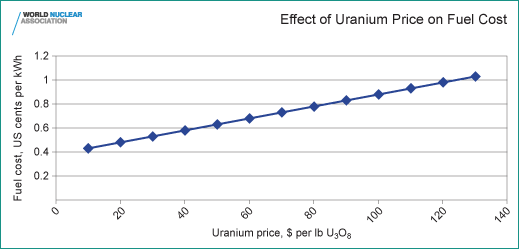

The impact of varying the uranium price in isolation is shown below in a worked example of a typical US plant, assuming no alteration in the tails assay at the enrichment plant.

The Economics of Nuclear Power

Fuel costs for nuclear plants are a minor proportion of total generating costs, though capital costs are greater than those for coal-fired plants and much greater than those for gas-fired plants. In assessing the economics of nuclear power, decommissioning and waste disposal costs are fully taken into account.

Assessing the relative costs of new generating plants utilising different technologies is a complex matter and the results depend crucially on location. Coal is, and will probably remain, economically attractive in countries such as China, the USA and Australia with abundant and accessible domestic coal resources as long as carbon emissions are cost-free. Gas is also competitive for base-load power in many places, particularly using combined-cycle plants, though rising gas prices have removed much of the advantage.

Nuclear energy is, in many places, competitive with fossil fuels for electricity generation, despite relatively high capital costs and the need to internalise all waste disposal and decommissioning costs. If the social, health and environmental costs of fossil fuels are also taken into account, the economics of nuclear power are outstanding.

The cost of fuel

From the outset the basic attraction of nuclear energy has been its low fuel costs compared with coal, oil and gas-fired plants. Uranium, however, has to be processed, enriched and fabricated into fuel elements, and about half of the cost is due to enrichment and fabrication. In the assessment of the economics of nuclear power allowances must also be made for the management of radioactive used fuel and the ultimate disposal of this used fuel or the wastes separated from it. But even with these included, the total fuel costs of a nuclear power plant in the OECD are typically about a third of those for a coal-fired plant and between a quarter and a fifth of those for a gas combined-cycle plant.

Fuel costs are one area of steadily increasing efficiency and cost reduction. For instance, in Spain the nuclear electricity cost was reduced by 29% over 1995-2001. This involved boosting enrichment levels and burn-up to achieve 40% fuel cost reduction. Prospectively, a further 8% increase in burn-up will give another 5% reduction in fuel cost.

Uranium has the advantage of being a highly concentrated source of energy which is easily and cheaply transportable. The quantities needed are very much less than for coal or oil. One kilogram of natural uranium will yield about 20,000 times as much energy as the same amount of coal. It is therefore intrinsically a very portable and tradeable commodity.

The fuel's contribution to the overall cost of the electricity produced is relatively small, so even a large fuel price escalation will have relatively little effect (see below). Uranium is abundant.There are other possible savings. For example, if used fuel is reprocessed and the recovered plutonium and uranium is used in mixed oxide (MOX) fuel, more energy can be extracted. The costs of achieving this are large, but are offset by MOX fuel not needing enrichment and particularly by the smaller amount of high-level wastes produced at the end. Seven UO2 fuel assemblies give rise to one MOX assembly plus some vitrified high-level waste, resulting in only about 35% of the volume, mass and cost of disposal.

Assessing the relative costs of new generating plants utilising different technologies is a complex matter and the results depend crucially on location. Coal is, and will probably remain, economically attractive in countries such as China, the USA and Australia with abundant and accessible domestic coal resources as long as carbon emissions are cost-free. Gas is also competitive for base-load power in many places, particularly using combined-cycle plants, though rising gas prices have removed much of the advantage.

Nuclear energy is, in many places, competitive with fossil fuels for electricity generation, despite relatively high capital costs and the need to internalise all waste disposal and decommissioning costs. If the social, health and environmental costs of fossil fuels are also taken into account, the economics of nuclear power are outstanding.

The cost of fuel

From the outset the basic attraction of nuclear energy has been its low fuel costs compared with coal, oil and gas-fired plants. Uranium, however, has to be processed, enriched and fabricated into fuel elements, and about half of the cost is due to enrichment and fabrication. In the assessment of the economics of nuclear power allowances must also be made for the management of radioactive used fuel and the ultimate disposal of this used fuel or the wastes separated from it. But even with these included, the total fuel costs of a nuclear power plant in the OECD are typically about a third of those for a coal-fired plant and between a quarter and a fifth of those for a gas combined-cycle plant.

In March 2011, the approx. US $ cost to get 1 kg of uranium as UO2 reactor fuel (at current spot uranium price):

| Uranium: | 8.9 kg U3O8 x $146 | US$ 1299 |

|---|---|---|

| Conversion: | 7.5 kg U x $13 | US$ 98 |

| Enrichment: | 7.3 SWU x $155 | US$ 1132 |

| Fuel fabrication: | per kg | US$ 240 |

| Total, approx: | US$ 2769 |

At 45,000 MWd/t burn-up this gives 360,000 kWh electrical per kg, hence fuel cost: 0.77 c/kWh.

Uranium has the advantage of being a highly concentrated source of energy which is easily and cheaply transportable. The quantities needed are very much less than for coal or oil. One kilogram of natural uranium will yield about 20,000 times as much energy as the same amount of coal. It is therefore intrinsically a very portable and tradeable commodity.

The fuel's contribution to the overall cost of the electricity produced is relatively small, so even a large fuel price escalation will have relatively little effect (see below). Uranium is abundant.There are other possible savings. For example, if used fuel is reprocessed and the recovered plutonium and uranium is used in mixed oxide (MOX) fuel, more energy can be extracted. The costs of achieving this are large, but are offset by MOX fuel not needing enrichment and particularly by the smaller amount of high-level wastes produced at the end. Seven UO2 fuel assemblies give rise to one MOX assembly plus some vitrified high-level waste, resulting in only about 35% of the volume, mass and cost of disposal.

Nuclear Fussion

Nuclear energy can also be released by fusion of two light elements (elements with low atomic numbers). The power that fuels the sun and the stars is nuclear fusion. In a hydrogen bomb, two isotopes of hydrogen, deuterium and tritium are fused to form a nucleus of helium and a neutron. This fusion releases 17.6 MeV of energy. Unlike nuclear fission, there is no limit on the amount of the fusion that can occur.

Subscribe to:

Posts (Atom)